|

![]()

Processing cultured pearls begins immediately after harvesting. In most cases, pearls fresh from the sea are washed, sized and separated into broad categories. These raw materials are then sold or auctioned off in lots to pearl processors.

Processing cultured pearls begins immediately after harvesting. In most cases, pearls fresh from the sea are washed, sized and separated into broad categories. These raw materials are then sold or auctioned off in lots to pearl processors.

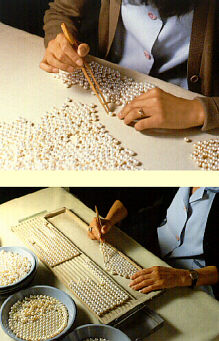

The processor must first determine the type of jewelry for which each cultured pearl would be most appropriate. Those to be mounted in brooches, rings, pendants and tie pins are drilled about halfway through. The majority are drilled completely through, for necklaces.

Next, most pearls (other than the South Sea variety) are submerged in a solution to help dissolve any organic impurities that may have caused natural stains, discolorations or blemishes.

The cultured pearls are now passed through a series of sieves to separate them by size. They are then further classified by quality.

The cultured pearls are now passed through a series of sieves to separate them by size. They are then further classified by quality.

The critical evaluation of each pearl's shape, color and luster, as well the thickness of its nacreous coating and surface cleanliness, takes great expertise.

As an example, tints may range from light to dark, through every imaginable rainbow hue: pink, silver, champagne, cream, gold, green, blue or gray. Each major species of oyster tends to produce a generic color range, with dozens of permutations of its own.

The cultured pearls are now grouped according to size and other similarities. Matching pearls are strung into 14-inch or 16-inch strands. Loose pearls, to be used for other types of jewelry, are bagged into individual lots. From the processor, they move on to wholesalers before gracing the showcases of jewelers throughout the world.